The battery laboratory is one of the five laboratories of the inspection department. It carries out testing activities in technical fields such as battery electrical performance and safety performance, covering various announcements and commissioned tests of battery cells, battery modules, battery packs, and battery clusters. , Up to now, there are 70 sets of main test equipment, with a total investment of about 40 million.

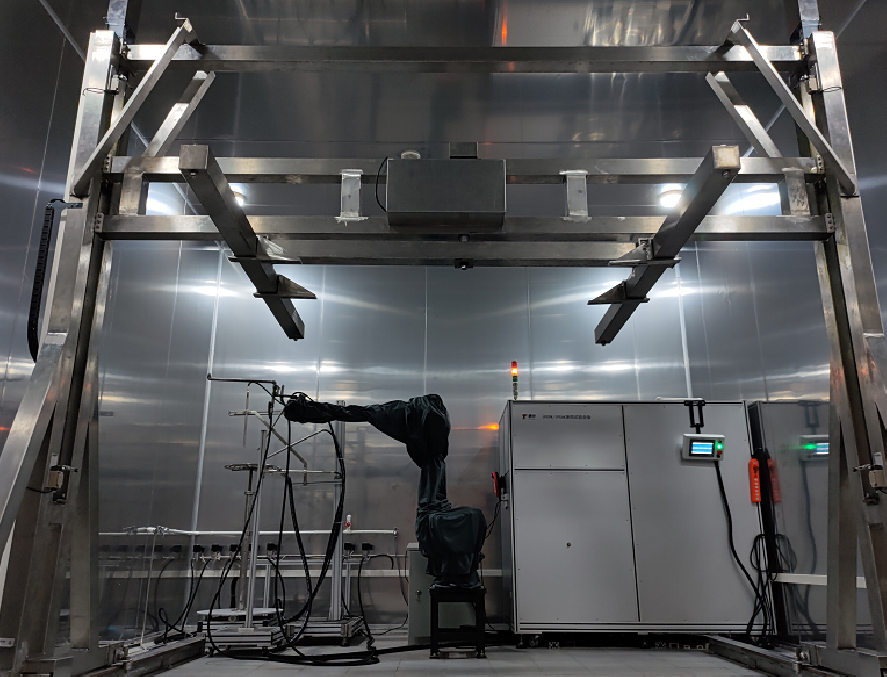

Battery pack charging and discharging equipment

Single charge and discharge equipment

Environmental box

low pressure tank

20t three comprehensive

IPX9K protective equipment

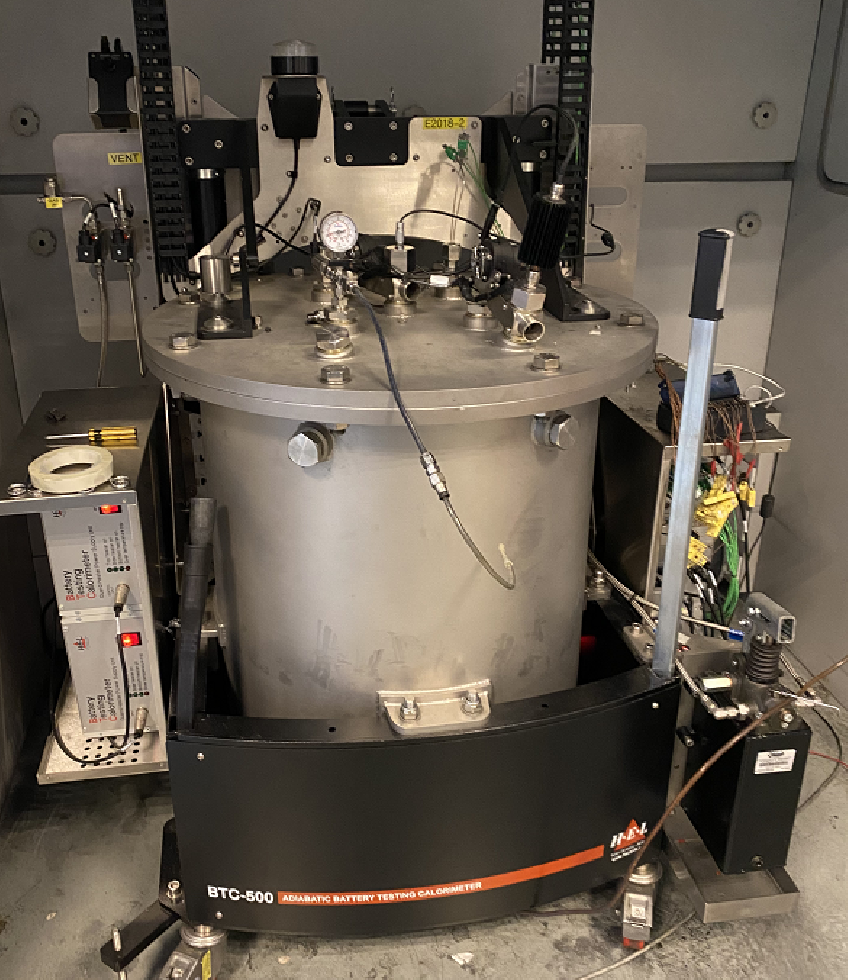

Adiabatic calorimeter

Address:No. 6 Shangjian Road, Tianyuan District, Zhuzhou City, Hunan Province TEl:0731- 28668066 Email:service@hnattc.com (投诉邮箱)

COPYRIGHT © 2022 HNATTC All Rights Reserved. 湘ICP备2022008534号

湘公网安备 43021102000320号

湘公网安备 43021102000320号